Description

In addition to being durable in continuous duty applications with harsh, poor lubricity fluids, it is a self-priming and quiet-running vane pump. It is ideal in a wide variety of transfer and circulating applications with non-corrosive fluids such as oils, fuels and coolants. Built with long-term industrial applications in mind, it can produce over 60 psi pressure at nominal voltages of 12 thru 24vdc. It performs well with high viscosity fluids down to very cold temperatures. As a positive displacement pump it will self-prime and is more efficient and quiet than a gear pump.

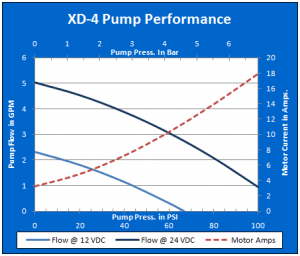

Voltage and Flow

The XD-4s TENV permanent magnet DC motor can be run anywhere between 10 and 27 VDC. As the voltage increases, the motor will turn faster causing more flow. At 12 VDC the pump puts out about 1.75 GPM. At 24VDC the pump makes about 4 GPM.

The voltage can also be varied within this range to set the pump flow to meet the demands of an application. Verifying the voltage can be done actively with electronics using feedback from other system states or simply kept within operating parameters by using a current limiting power supply or with an appropriate resistor.

Variable Voltage Example Application 1:

A fuel “day tank” needs to be replenished to a given level within a certain range regardless of varying engine fuel demand. A sensor can be used to monitor the tank level. The pump voltage can then be electronically varied to regulate motor speed and pump flow to constantly maintain the desired fuel level.

Variable Voltage Example Application 2:

An oil based heat exchange circuit needs to be able to start up when the oil is cold and thick without overloading the pump. Since the system starts off cold, lower flow is acceptable as long as the pump motor is not overloaded. A current limiting power supply can be used that will keep the pump below 7 amps at startup by reducing the voltage and therefore the pump speed. As the oil heats up and thins out, the pump will gradually speed up until the power supplies nominal voltage is reached allowing full pump speed and flow.

Duty Cycle and Circuit Protection

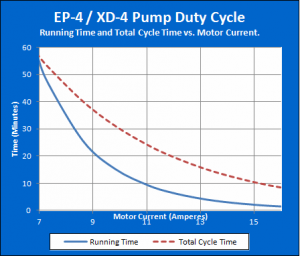

The XD-4 pump’s permanent magnet motor is capable of doing an extraordinary amount of work for its size but it is also the limiting factor for duty cycle. When it is loaded beyond about 7 amps. at room temperature it will begin to make heat at a rate that is higher than it can dissipate heat. There are a number of factors that come into play in determining a safe duty cycle such as ambient temperature and airflow. In complex applications, the simplest way to determine the duty cycle may be thru direct experimentation. See the chart below for basic duty cycle guidelines. Adding active cooling to the motor can substantially improved duty cycle. Generally if the outside of the motor in maintained below 175°f (80°c) motor life will be preserved.

The motor current varies with the viscosity and the pressure required to pump the fluid through the system. Many oil-based fluids have a substantial viscosity response to cold temperatures causing high motor current draws. We recommend the Bussmann CB251-15 breaker be used on the power supply line to protect the motor from thermal overload under adverse conditions. These particular breakers have an amp/time curve that closely matches the motor/pump combination to properly protect the pump within its operating envelope for up to 3 minutes of cumulative motor on time.